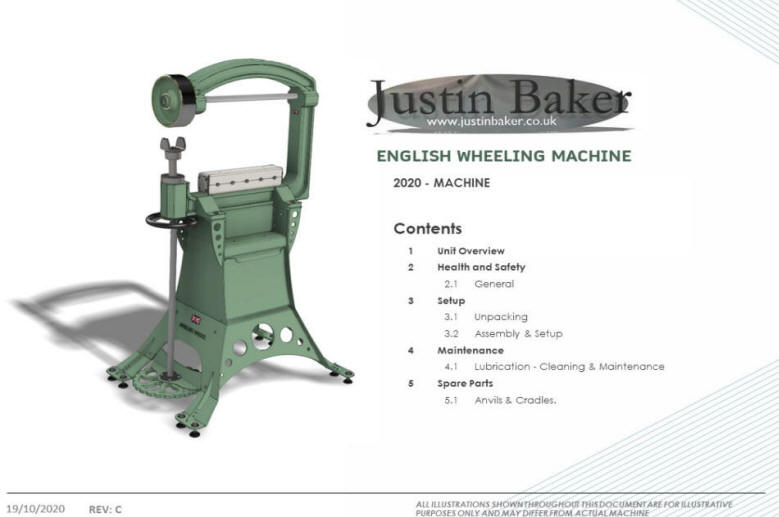

Specifications

For a PDF, click the image above

This sturdy machine is cast in a good

old-fashioned foundry in Stoke-on-Trent, which

is one of only a few capable of the required

substantial sustained pour from the crucible in

order to produce the stiff ribbed frame needed

with a 600mm deep throat for these machines.

Featuring a useful working throat depth of 24

inches (610mm), it has a large 7.8 inch (200mm)

diameter top anvil cut from a huge chunk of EN16

machine steel, it’s 2.75 inch (70mm) wide face

is scalloped out on each face to reduce inertia,

and aid hand movement, for those tight corners.

Five lower anvils are supplied 2.75 inch (70mm)

with the machine. All are precision CNC cut from

machine steel, from an almost flat, to a very

tight curve, and come with a tray for easy

access to the desired profile.

These are;

· R400 (15.7”) with a contact area or blow width of

12.0mm

· R300 (11.8”) with blow width of 8.5mm

· R200 (7.8”) with blow width of 7.2mm

· R100 (3.9”) with blow width of 6.35mm

· R50 (1.9”) with blow width of 4.0mm

This machine features a unique adjustable anvil

cradle, allowing perfect alignment of the

contact patch or blow, reducing panel marks,

allowing good stretch overlaps, while reducing

the need for any further planishing.

.jpg)

.jpg)